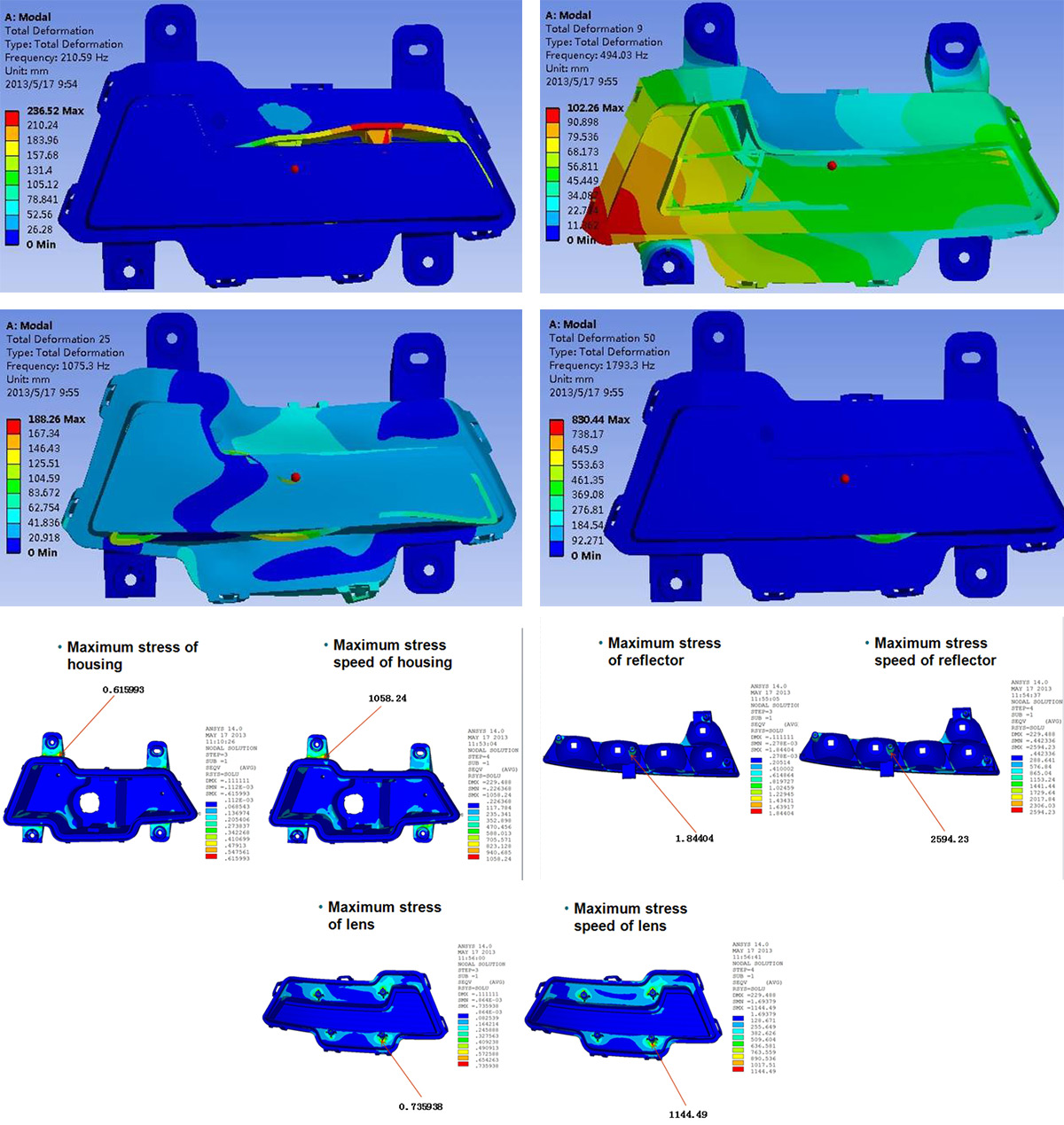

1. By vibration simulation analysis, we can get the stress and the highest of stress speed of each part.

2. Then, unified computing with the fatigue life of the material, we can judge if the chosen material is qualified to the resistance requirements.

| Vibration Frequency(Z) | Power Density Spectrum |

| 10 | 0.208 |

| 55 | 0.0677 |

| 180 | 0.0026 |

| 300 | 0.0026 |

| 360 | 0.00146 |

| 1000 | 0.00146 |

| No. | Part Name | Material | Density | Elasticity Modulus | Tensile Strength | Poisson's ratio |

| 1 | Lens | PC | 1200 | 2400 | 67 | 0.3 |

| 2 | Reflector | PC | 1200 | 2400 | 67 | 0.3 |

| 3 | Housing | PP+TD20% | 1040 | 1800 | 20 | 0.3 |

| Part | Stress(MPa) | Stress(MPa) | Actual cycle number | Damage | Total damage |

| Lens | 1σ(0.74) | 1.64E24 | 5.32E7 | 3.24E-17 | 7.14E-13 |

| 2σ(1.48) | 5.69E20 | 5.24E7 | 9.21E-14 | ||

| 3σ(2.22) | 5.39E18 | 3.35E6 | 6.22E-13 | ||

| Housing | 1σ(0.62) | 1.15E19 | 1.25E8 | 1.08E-11 | 2.09E-07 |

| 2σ(1.24) | 4.01E15 | 5.05E7 | 1.25E-08 | ||

| 3σ(1.86) | 3.79E13 | 7.93E6 | 2.08E-07 | ||

| Reflector | 1σ(1.84) | 4.66E19 | 4.86E7 | 1.04E-12 | 2.13E-08 |

| 2σ(3.68) | 1.61E16 | 2.11E6 | 1.30E-09 | ||

| 3σ(5.52) | 1.52E14 | 3.06E6 | 1.99E-08 |

The total damage of reflector , housing , lens is less than 1, so the fatigue damage will not happen

Tel:+ 86-576-84203933

Fax: +86-576-84203922

Email:djcn@djcn.com.cnAdd:No. 25, Chaoyuan Road, Xinqian Development, Huangyan, Taizhou, Zhejiang